VFD is a kind of power control equipment which USES frequency conversion technology and microelectronic technology to control ac motor by changing the working power frequency of the motor. It is mainly composed of rectifier (ac to dc), filter, inverter (dc to ac), brake unit, drive unit, detection unit and micro-processing unit. VFD relies on the cut-off of internal IGBT to adjust the output power supply voltage and frequency. According to the actual needs of the motor to provide its required power supply voltage, then achieve the purpose of energy saving, speed regulation.

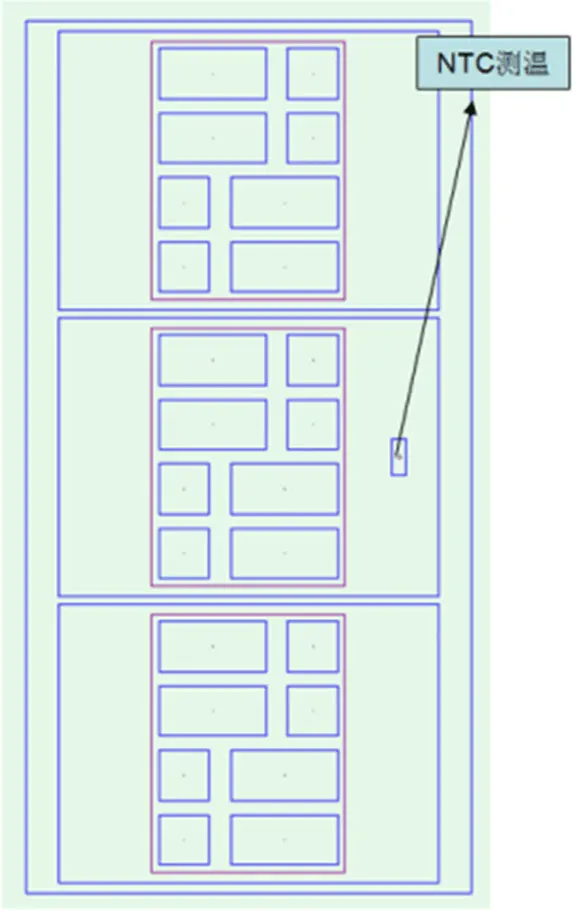

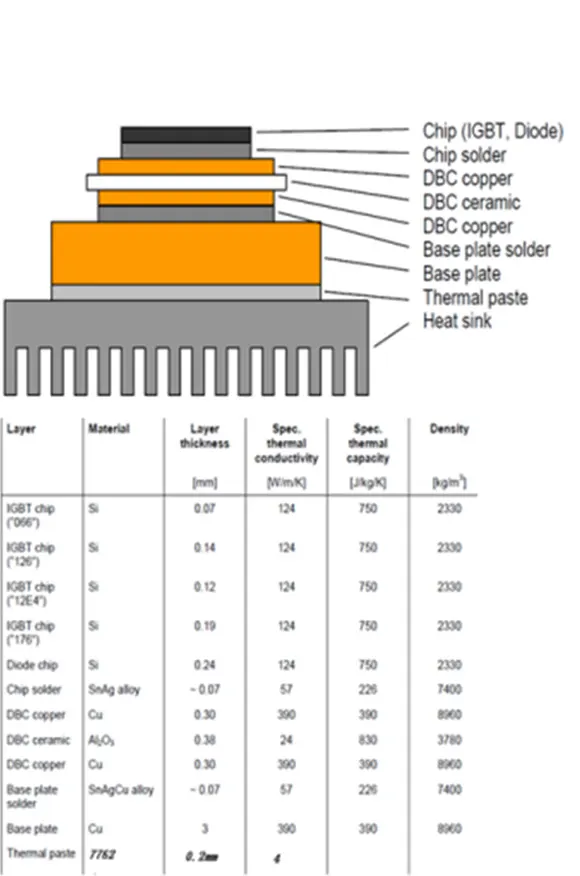

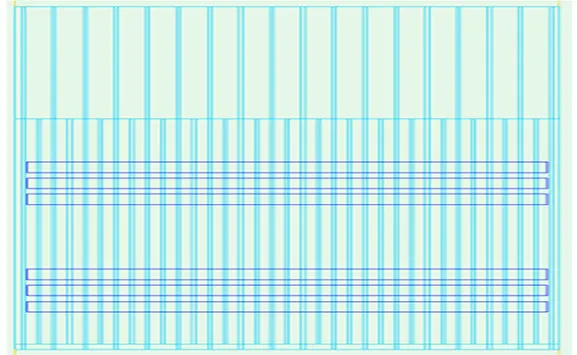

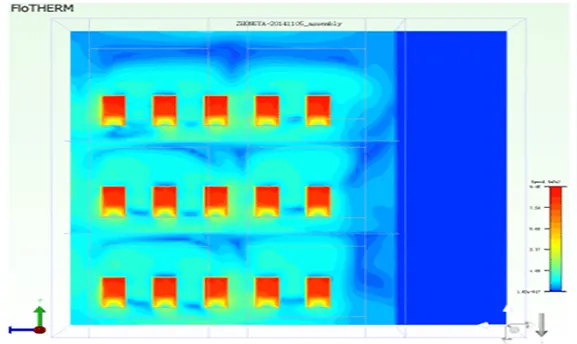

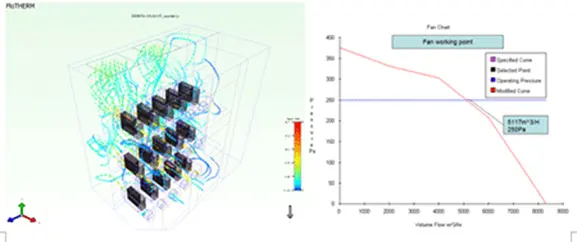

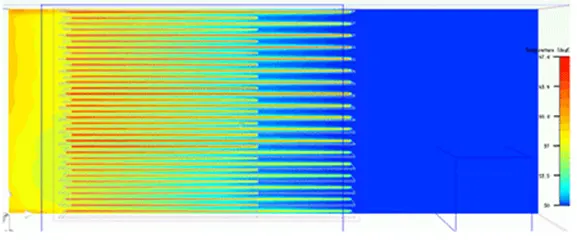

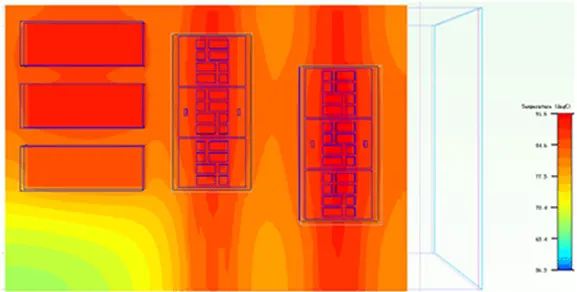

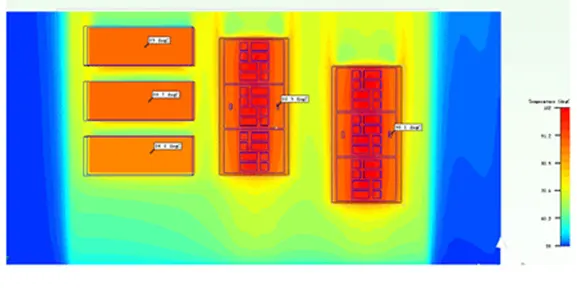

The heat dissipation of VFD has great influence on its performance and working life. A good heat dissipation solution for the VFD is undoubtedly important, especially in the case of fierce competition, good heat dissipation can improve the quality of the VFD and enhance the competitiveness. TONGYU Thermal provides advanced heat dissipation technology and service to many VFD manufacturer for many years, provides customized heat dissipation solutions for the customer VFD products, also provides effective thermal simulation, thermal testing and other technical support, escorting for the stability play of VFD products’ performance.

The heat dissipation of VFD has great influence on its performance and working life. A good heat dissipation solution for the VFD is undoubtedly important, especially in the case of fierce competition, good heat dissipation can improve the quality of the VFD and enhance the competitiveness. TONGYU Thermal provides advanced heat dissipation technology and service to many VFD manufacturer for many years, provides customized heat dissipation solutions for the customer VFD products, also provides effective thermal simulation, thermal testing and other technical support, escorting for the stability play of VFD products’ performance.

Current Location:

Current Location: