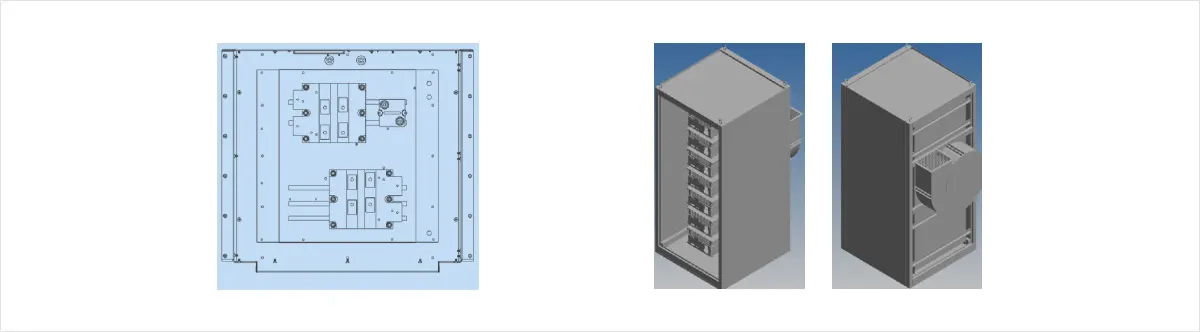

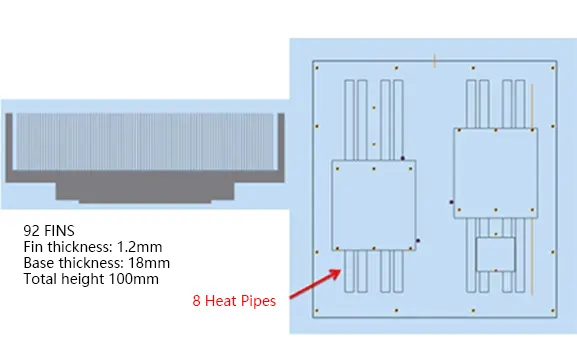

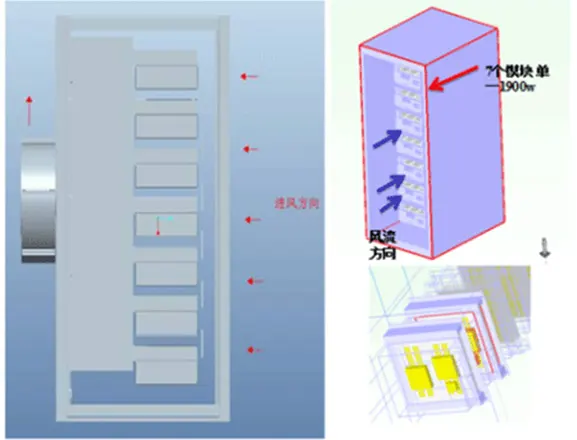

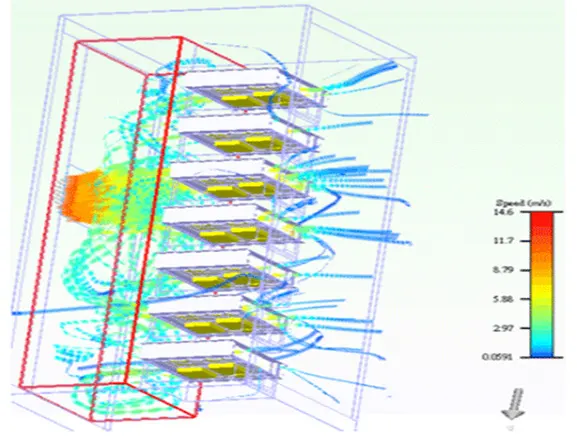

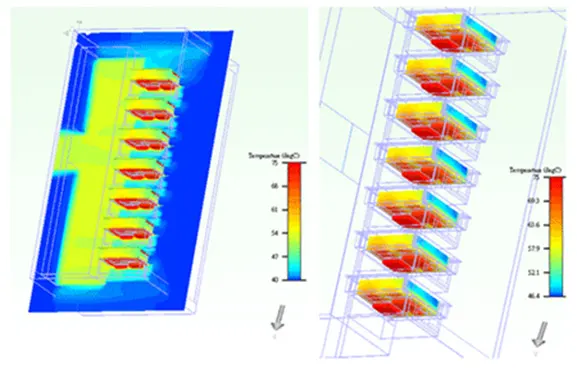

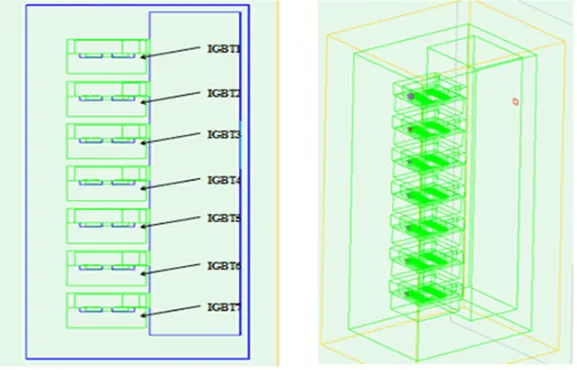

The static reactive power compensation device (SVC) is a kind of important equipment for comprehensively controlling voltage fluctuation, flicker, harmonic and voltage imbalance. SVG is a new static reactive power compensation device which is more advanced than SVC. It is an important part of FACTS technology and custom power (CP) technology. It is the development direction of modern reactive power compensation device. They are widely used in power transmission and distribution systems: long-distance power transmission, urban secondary substation (35/110kv), arc furnace, mill hoist and other heavy industry loads, regional power grid, pv power supply, wind farm, electric locomotive power supply and other fields. SVG is a high-heat element, which needs to be combined with a radiator with excellent heat dissipation performance to ensure the stable operation of other elements and increase the working time.

Tongyu thermal has rich technical experience in SVC/SVG cooling and can provide solutions with excellent heat dissipation performance, including providing technical service support in natural cooling, forced air cooling and liquid cooling.

Tongyu thermal has rich technical experience in SVC/SVG cooling and can provide solutions with excellent heat dissipation performance, including providing technical service support in natural cooling, forced air cooling and liquid cooling.

Current Location:

Current Location: