According to the provisions of the State Grid, the proportion of distributed generation such as photovoltaic and wind power should not exceed 10% of the power grid, and more than 10% of the grid will be added to the energy storage system. Because photovoltaic system and wind power system do not use energy storage system in grid-connected power generation, there will be some adverse effects on the grid. If the scale of wind energy and photovoltaic power system continues to expand and the proportion of photovoltaic power in the system continues to increase, these effects can not be ignored. Through the analysis of the characteristics of photovoltaic power generation, it can be seen that the impact of photovoltaic power generation system on the grid is mainly caused by the instability of photovoltaic power supply. In order to make the grid safer, stable and economic operation, it is generally required to install energy storage system. Therefore, the demand for energy storage system has increased in recent years.

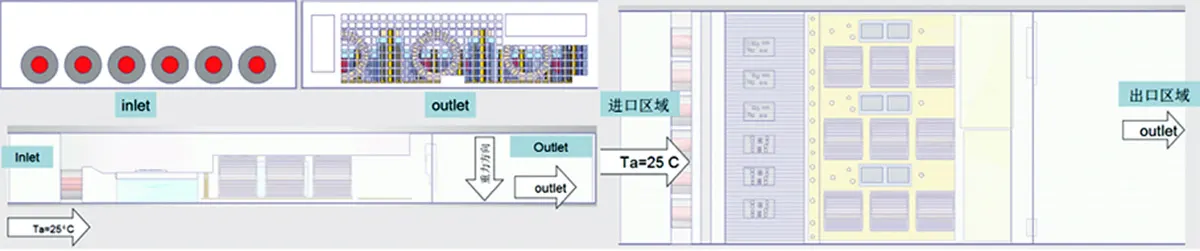

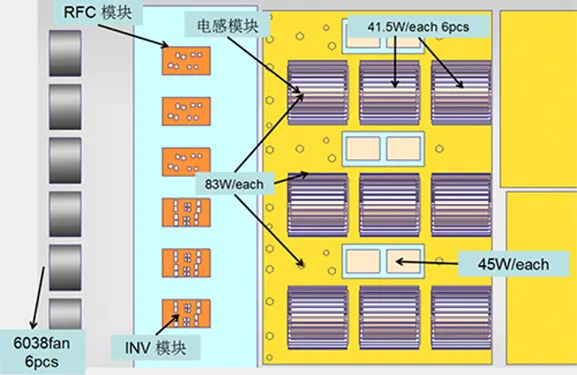

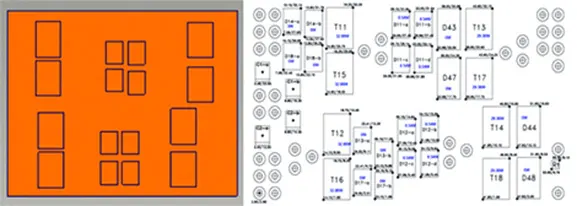

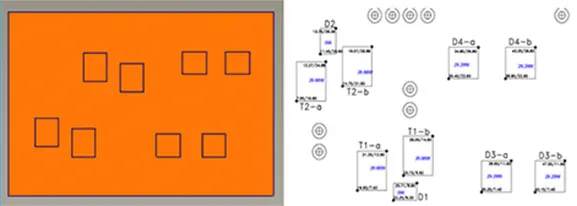

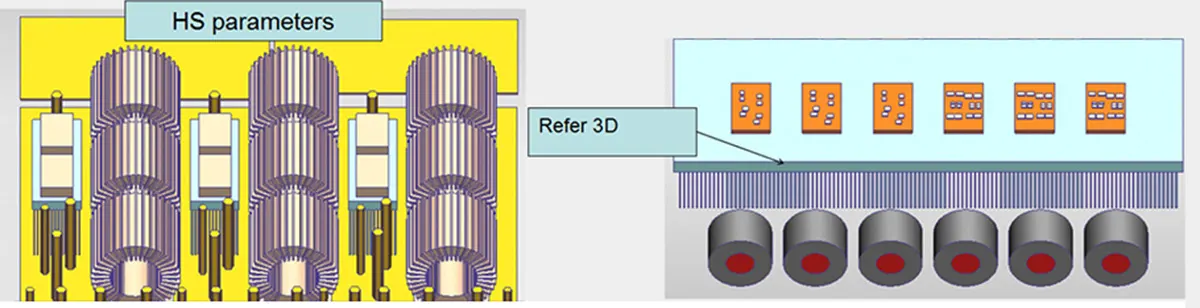

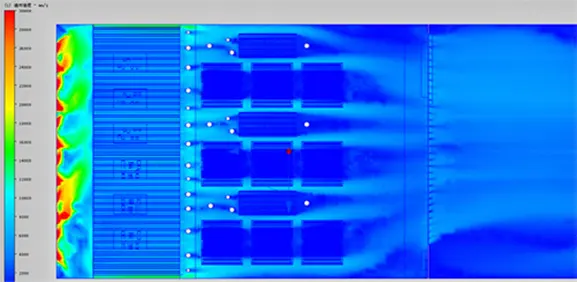

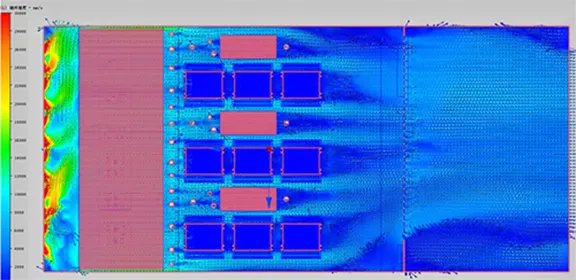

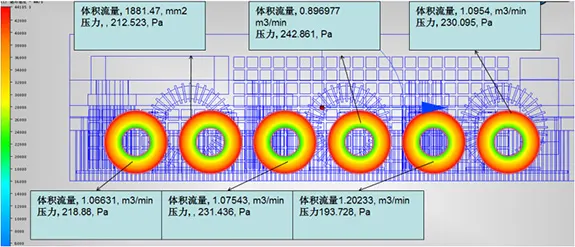

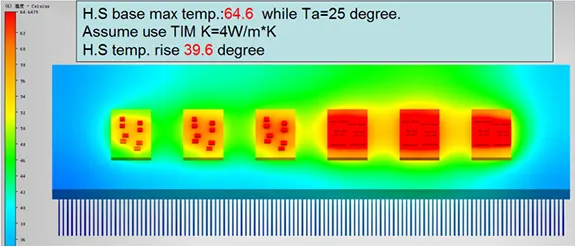

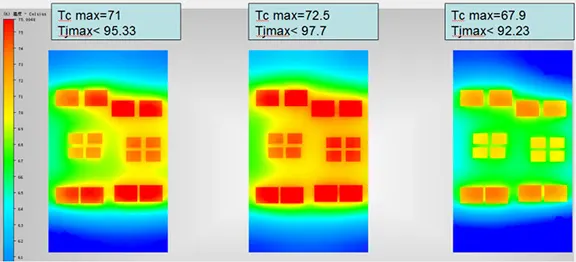

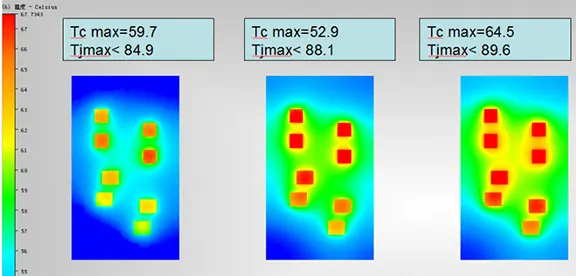

The stable operation of energy storage system is related to the safety and stability of power grid, so major energy storage system manufacturers attach importance to its quality, and among the factors affecting the stability of energy storage system, heat dissipation performance is undoubtedly the most important. Tongyu Thermal Energy focuses on high-power heat dissipation, and has rich experience in the research and development and manufacture of radiators for energy storage systems. Tongyu Thermal Management Engineer can provide heat dissipation solutions at the beginning of the design of energy storage systems, and also can optimize the heat dissipation performance of energy storage systems. By accumulating abundant thermal design data, Tongyu can provide accurate thermal simulation and thermal management test data.

The stable operation of energy storage system is related to the safety and stability of power grid, so major energy storage system manufacturers attach importance to its quality, and among the factors affecting the stability of energy storage system, heat dissipation performance is undoubtedly the most important. Tongyu Thermal Energy focuses on high-power heat dissipation, and has rich experience in the research and development and manufacture of radiators for energy storage systems. Tongyu Thermal Management Engineer can provide heat dissipation solutions at the beginning of the design of energy storage systems, and also can optimize the heat dissipation performance of energy storage systems. By accumulating abundant thermal design data, Tongyu can provide accurate thermal simulation and thermal management test data.

Current Location:

Current Location: